Precision, Pressure, and a Pitch: The Allen Jones Legacy

By Mel Ohlinger

CEO of OhmCo

Before “touch-free” and “touchless” became buzzwords, they were the radical vision of Allen Jones—a mechanically minded Kiwi whose ingenuity changed the car wash industry forever. Today, drivers around the world enjoy high-tech washes that never touch their vehicles. Among the most iconic examples is the PDQ LaserWash: laser-precise, high-pressure, and renowned for delivering safety, speed, and shine. But few know the story of the New Zealand engineer who made it all possible.

The Spark of an Idea

Allen Jones grew up in New Zealand and launched his career in industrial automation, designing machines to streamline complex manufacturing processes. But inspiration struck during a stop at a gas station in the 1980s. Convenience stores were booming, but the car washes attached to them were outdated, inefficient—and often caused damage to vehicles.

These rollover-style systems with nylon bristles had dominated the petroleum industry for decades, but they had a poor reputation for cleaning performance, reliability, and profitability. “They were usually out of order,” Allen recalls, “and often offered as a free add-on after filling up with petrol.”

He saw an opportunity: What if this neglected part of the gas station could actually clean cars safely—and make money doing it?

Allen began to wonder—what if a standardized, scalable machine could be built to replace the one-off systems he’d been designing? What if it could use sensors, or even beams of light—lasers—to clean cars without contact?

As he began developing his concept, Allen focused on operators who could benefit the most from this breakthrough—gas jobbers, oil companies, and owners of self-serve sites who might convert a bay or two to a new kind of in-bay automatic system. “I always sold the car wash owner,” Allen explains, “but I focused on the needs of their customer.”

The First LaserWash

In 1984, Allen began developing a new kind of car wash—one that relied entirely on high-pressure water and smart controls. Inspired by large-scale train-washing systems he’d seen in Chicago; he designed a gantry-style unit that mapped the vehicle envelope with sensors and cleaned with advanced chemistry and precision water jets. He called it the LaserWash. The name—suggested by his then father-in-law, Mike Majchrzak—perfectly captured the machine’s futuristic appeal. It was years ahead of its time and ready to reshape the industry.

From New Zealand to Green Bay, Wisconsin

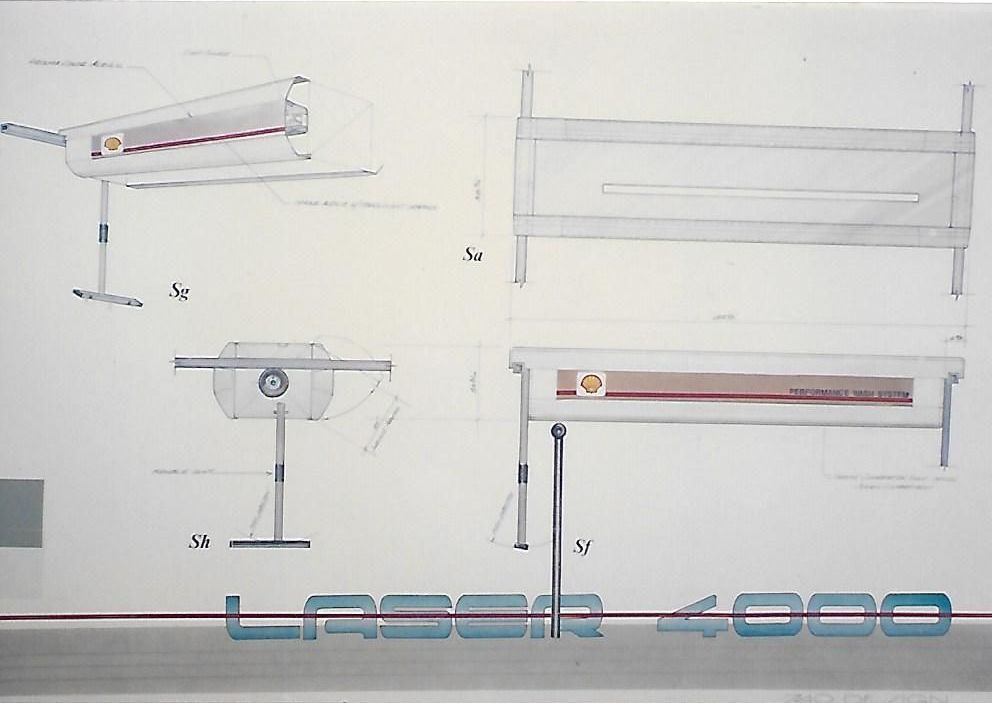

To commercialize the LaserWash, Allen founded the Pacific Car Wash Company and his team launched their New Zealand-manufactured, high-pressure LaserWash 3000 units into the U.S. market in 1986. But shipping from New Zealand posed serious challenges and costs. Facing a tough global economy, Allen made a bold move and relocated to the U.S. in 1988—bringing production, and his firstborn son Damon Jones, to Chicago. There, he began building the next-generation LaserWash 4000, which was introduced to the industry in 1989 at the McCormick Place Car Wash Show.

As Allen, Damon, and the Pacific Car Wash team prepared for that major trade show, their prototype was barely finished. They worked four straight days and nights to get the car wash show-ready. Damon remembers the paint still being wet as they set it up—and having to pick bugs out of the finish.

But the effort was worth it, because it was at that show that Allen crossed paths with Red Lewis—the heart of the Green Bay car wash community and founder of PDQ Manufacturing. Red had started PDQ in 1984 and was known for building his own equipment when nothing else met his standards. While most in the industry assumed PDQ stood for “Pretty Damn Quick,” Red gave it a more fitting meaning for his operation: Performance, Dependability, and Quality.

However, Red wasn’t immediately sold. He wanted to see real-world installations. So after visiting a few sites around Chicago in the following days, he saw Allen’s vision and was convinced that the LaserWash was the future of car washing. Allen and Red met again in Green Bay, where they agreed on terms of a merger—sealed with a handshake and stock options. From there, everything changed. Allen brought the invention; Red brought the platform to scale. Together, they launched LaserWash production in Wisconsin.

The Timing Was Perfect

By the early 1990s, the car wash industry was on the brink of a seismic shift due to changes in automotive paint. For decades, friction-based washes had ruled the landscape. Their spinning brushes functioned almost like buffing wheels—effective on the older lacquer and enamel finishes, which were tough enough to withstand the pressure.

But new environmental regulations required automakers to reduce VOC emissions. In response, they transitioned to basecoat/clearcoat paint systems with softer, water-based clear finishes. By 1994, nearly all vehicles featured these newer, more delicate coatings—finishes that did not respond well to harsh physical contact.

The shift validated Allen’s vision. What had once been a niche or novel idea was now a market necessity. Customers were worried about micro-scratches and clearcoat damage. Operators needed safer options. Customers wanted peace of mind. The market was primed for the LaserWash. Suddenly, everyone wanted—and needed—a “touch-free” way to wash.

Scaling a Revolution

The success of the LaserWash wasn’t just about smart engineering. It was about building trust. Operators who once doubted the power of a brushless wash soon shared stories of lower maintenance, happier customers, and better revenue. The LaserWash quickly earned a reputation for reliability—especially after surviving brutal Wisconsin winters while competitors failed. Allen, Red, and a third key player—Charlie Lieb—formed a powerhouse team. With relentless innovation and business savvy, they turned doubt into dominance. PDQ refined the system for different regions, climates, and car wash types. The LaserWash became a staple in gas stations, a hero in harsh environments, and a reliable in-bay automatic for self-serve sites.

One story that circulated widely among operators was about a LaserWash that ran flawlessly through one of the harshest Wisconsin winters on record, while other systems seized up in the cold. That rugged dependability helped elevate PDQ from niche innovator to industry leader.

PDQ also took things a step further. They dialed in the chemistry and calibration for different climates, ensuring that the LaserWash worked in coal towns, southern suburbs, and icy northern cities alike. It thrived in the petroleum industry as a premium add-on at gas stations, but it also became a standalone solution—often installed alongside self-serve bays in the in-bay automatic model we still see today.

At the same time, Allen kept innovating. With collaborators like Mark Cuddeback and Doug Diemel, he introduced dual chemical injectors, onboard dryers, heated soap systems, and vehicle contour-sensing. By 2000, the fifth-generation LaserWash—dubbed the G5—featured seven unique patents and a blend of mechanical simplicity and software intelligence. Allen’s drive pushed touch-free technology far beyond novelty—it became the standard. And once it took hold in Green Bay, the momentum was unstoppable.

They also nailed the branding. Instead of using the generic “touchless,” PDQ coined “Touch Free”—a cleaner, more distinctive term that stuck. National brands like Mobil took notice and began partnering with PDQ to install LaserWash systems across the U.S. and around the world. The LaserWash 4000 would go on to become one of the most successful in-bay automatics ever built.

One early installation at a Mobil convenience store in Boston captured just how impactful this shift was. Allen arrived at the brand-new twin LaserWash site with C-store executives in tow. When they asked the cashier how things were going, his response said it all: “We’re making more money washing cars than selling cigarettes—and with no damage or complaints.” At the time, cigarette sales were the highest source of income for these stores. That response marked more than just a success story—it was the beginning of the end for free car washes with a fill-up and the start of a new era of car wash profitability.

Allen’s Lasting Legacy

Allen Jones now resides in sunny California and continues to bring big ideas into new industries—but his legacy in the car wash world is undeniable. Without Allen, we wouldn’t have Washworld car washes. Without Allen, we wouldn’t have Petit Auto Wash Equipment. He holds a long list of patents that refined everything from spray arches to chemical control systems, vehicle profiling, and onboard drying, but he didn’t stop there. He kept driving our industry forward because technologies like the TouchFree Loading System and Smart 360 didn’t just improve car washing—they made intelligent wash bays possible. And because Allen dreamed big, the modern car wash became smarter, more accessible, and more precise.

But Allen’s mark on Green Bay didn’t end at the car wash.

He and his son Damon also introduced rugby to the region. Allen negotiated a $1-per-year lease for land and helped transform it into Green Bay’s first permanent pitch. They even fabricated the original goalposts using the same machines used to build the LaserWash. Those posts still stand—a testament to Allen’s craftsmanship and community spirit.

So yes, Allen Jones changed the way we wash cars. But he also changed the way Green Bay plays. His legacy lives on in every LaserWash bay, every spotless finish, and every try scored under Wisconsin skies. Because when Allen Jones builds something—whether it’s a car wash or a rugby field—it’s made to last. The LaserWash wasn’t just a machine. It was a clean break from the past and the start of a smarter future.

SHARE ONLINE